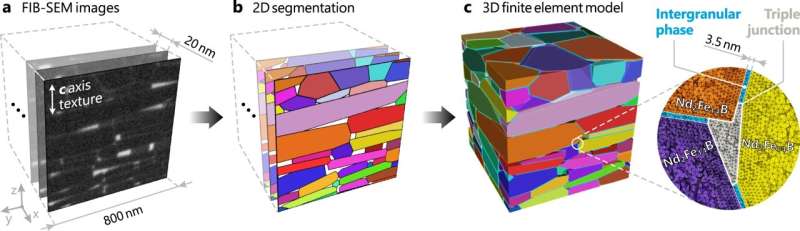

Development of tomography-based models. a A series of FIB-SEM images of a thermally deformed Nd-Fe-B magnet. b Image processing, including 2D segmentation and conversion of particle slices into point clouds. c Produce close-packed 3D convex grains isolated from each other by intergranular phases. The triple connection points are not visible except for a zoomed area showing the mesh around one of the connection points. Credit: npj computational materials (2024). DOI: 10.1038/s41524-024-01218-5

NIMS successfully simulated the magnetization reversal of Nd-Fe-B magnets using a large-scale finite element model based on tomography data obtained by electron microscopy.

This simulation reveals microstructural features that hinder coercivity, which quantifies a magnet’s resistance to demagnetization in opposing magnetic fields. New tomography-based models are expected to guide the development of sustainable permanent magnets with ultimate performance.

High-tech industries such as green power generation and electric transportation rely heavily on high-performance permanent magnets, among which NdFeB permanent magnets have the strongest performance and the largest demand. To date, the coercivity of industrial Nd-Fe-B magnets has been well below physical limits. To solve this problem, micromagnetic simulations can be performed on real models of magnets.

This study presents a new method for reconstructing the true microstructure of ultrafine-grained Nd-Fe-B magnets in large-scale models and has now been published in the journal npj computational materials.

Specifically, tomographic data from a series of 2D images obtained through scanning electron microscopy (SEM) combined with uniform focused ion beam (FIB) polishing can be converted into high-quality 3D finite element models.

This tomography-based approach is general and can be applied to other polycrystalline materials to solve a wide range of materials science questions.

Micromagnetic simulations based on tomography models reproduce the coercivity of ultrafine-grained Nd-Fe-B magnets and explain their mechanisms. Microstructural features related to coercivity and magnetization reversal nucleation are revealed.

The developed model can therefore be considered a digital twin of the Nd-Fe-B magnet – a virtual representation of the object designed to accurately reflect its physical properties.

The proposed digital twin of the Nd-Fe-B magnet is accurate enough to reproduce the microstructure and magnetic properties that can be used for inversion problems when designing on-demand high-performance permanent magnets.

For example, when researchers input the magnetic properties required for a specific application, such as traction or variable magnet motors, a data-driven research pipeline with an integrated digital twin will be able to propose optimal compositions, processing conditions and microstructures. magnets, significantly reducing development time.

More information:

Anton Bolyachkin et al., Tomography-based digital twin of Nd-Fe-B permanent magnets, npj computational materials (2024). DOI: 10.1038/s41524-024-01218-5

Provided by National Institute of Materials Science

citation: Scientists use large finite element model to simulate magnetization reversal of Nd-Fe-B magnet (2024, April 26), Retrieved April 27, 2024, from https://phys.org/news/2024-04- scientists-simulate-magnetization-reversal-fe.html

This document is protected by copyright. No part may be reproduced without written permission except in the interests of fair dealing for private study or research purposes. Content is for reference only.

#Scientists #large #finite #element #model #simulate #magnetization #reversal #NdFeB #magnet

Image Source : phys.org