The Space Development Agency’s plan to deploy hundreds of missile warning and communications satellites over the next few years is still in the early stages of execution, but one lesson defense companies are learning from the effort is the importance of cultivating reliable supply chains.

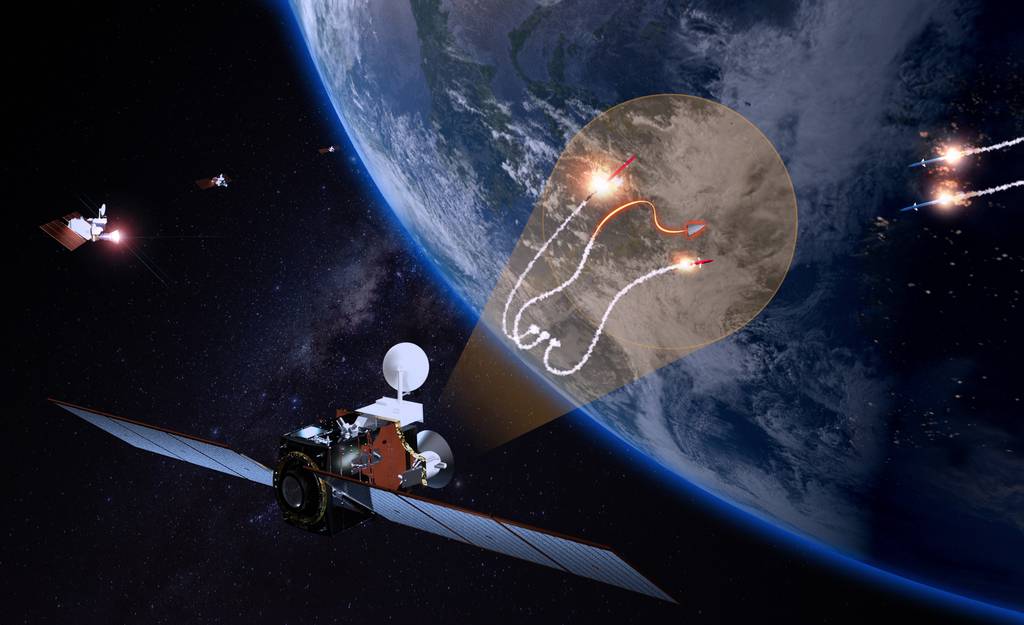

L3Harris is one of them. The Melbourne, Florida-based company has been contracted to deliver 38 satellites as part of the first three tranches of the SDA missile tracking constellation, four of which were launched in February.

The company faced supply chain challenges while developing its first four spacecraft, most notably the satellite bus provided by Moog Inc. credibility within SDA and lays the foundation for the future.

A Moog spokesperson told C4ISRNET that the company plans to vigorously defend against the allegations and will respond in court when appropriate.

Meanwhile, L3Harris selected Maxar to build the satellite buses for its Tranche 1 and Tranche 2 satellites.

Kelle Wendling, President of L3Harris’ Space Systems Division, recently spoke with C4ISRNET to discuss the challenges of developing a diverse yet mature supply chain for small satellites and provide insight into how the company has adapted its strategy over the past few years.

This interview has been edited for length and clarity.

You contracted for the first three batches of SDA missile tracking satellites, so you have already delivered some spacecraft and have others in various stages of design and development. What are some of the lessons you learned early on that you can apply to your most recent contract?

We learned many lessons from Phase 0 to Phase 1. We’re still grappling with the fact that it’s still very rocket science and the technology we need isn’t built to stock. We definitely have the opportunity space to make sure that we get supply chain contracts in place early, that we work hand-in-hand with them to make sure the mission is successful, and that we have a timeline that’s tightly put together, especially given the dates and timeframes that some of the SDA’s are working on .

I think the most important thing going from Phase 0 to Phase 1 and even to Phase 2 is that we did limit non-recurring engineering because the award was given in January. We limit NRE so that we can limit the risk and then try to keep our supply chains somewhat prepared as we start to move into this real phase of proliferation. We are the only company participating in all three phases. Making sure our designs continued to mature but not change too much so we could reduce risk and move forward was a really big effort for three teams.

We heard SDA Director Derek Tournear talk about supply issues for specific components and systems such as crosslinks and radios. Where do most of your supply challenges come from?

You can probably pick out the top five spots that are really challenging on one hand.I think [optical intersatellite links] is one. Of course, who you choose as your bus provider is a very, very important factor. I’d love to tell you that buses have been commoditized, but they haven’t yet. This is still rocket science. You have to make sure it’s suitable for the mission and that you can get the spacecraft when you need it.

The same goes for radios. We have a little advantage because we have a department that provides our encryption capabilities and they provide us with the radios.

How do you balance the desire to have a diverse supply base with the need for consistency? Did you have to make a lot of changes on the supplier side?

There’s always a balance between, do I go all-in with my partners and really put all my money here, or do I have some diversity in my supply base that might not give me the best, most Cost effective option, but at least I have backup. We actually had to use a mixture of the two.

We are now in the diffusion phase where supplier diversity is really starting to come into play. In fact, we’re talking about 14, 16, 18 satellites at a time. This is huge for the space world. Not all of our suppliers can actually do this themselves. So we have to strike a balance of, okay, let’s double down and select some subsystem providers that may be exclusive. On other fronts, we’re going to have a variety of solar array capabilities or focal planes and other things so that we make sure that we have diversity in case there are challenges with the supply base.

You mentioned efforts to limit non-recurring engineering, which refers to the one-time costs associated with developing new features. Frank Calvelli, assistant secretary of the Air Force for space acquisition and integration, said this is a key tenet of space acquisition. What are the practical challenges in reducing NRE?

As we discussed supplier diversity, if you dilute [your supply chain] Having multiple vendors is too much, and you can’t necessarily get their investment and attention and have that partnership. However, whether it is the optical link, focal plane or bus provider, we know there are some key areas that can put some stress on the system.

It’s not yet to the point where the next level subsystem providers are really as powerful as we need them to be. Then, the third-tier suppliers below them are more vulnerable in the ecosystem because they are smaller companies with very niche technologies.

This is still something we have to work on. But we’ve been very intentional about where we want to have dual sources. We have dual-sourced designs and dual-sourced parts to ensure we can meet manufacturability as well as the quantities and timelines we have signed SDA’s for.

Courtney Albon is C4ISRNETs’ space and emerging technologies reporter. She has been covering the U.S. military since 2012, focusing on the Air Force and Space Force. She reports on some of the Department of Defense’s most significant acquisition, budget and policy challenges.

#L3Harris #supporting #small #satellite #supply #chain

Image Source : www.c4isrnet.com