A potential new way to travel into space is being launched by Rocket Lab’s Electron rocket from Launch Complex 1 on New Zealand’s Mahia Peninsula.

The mission, called Swarm Start, will deliver two payloads into sun-synchronous orbit. The flight takes off at 22:32 UTC on April 23, 2024.

One of the mission’s two payloads is NASA’s Advanced Composite Solar Sail System (ACS3). The goal is to test a new composite material that can be folded inside something as small as a CubeSat and still deploy and remain rigid in space.

In this test, the solar sail was designed to be installed inside a 12-unit (12U) CubeSat, which measures approximately 23 x 23 x 34 centimeters (9 x 9 x 13 inches). This is about the size of a microwave oven.

Solar sails require the deployment of a large metal plate that acts like a sail on a sailboat. Similar to a boat, it uses a boom to deploy the sails. Rather than using chemical or electric propulsion, these sails use sunlight and solar wind to help propel a spacecraft or satellite.

For this mission, raising the sails was the second goal. The first goal was to unfurl the entire sail in about 25 minutes and see how well it held up.

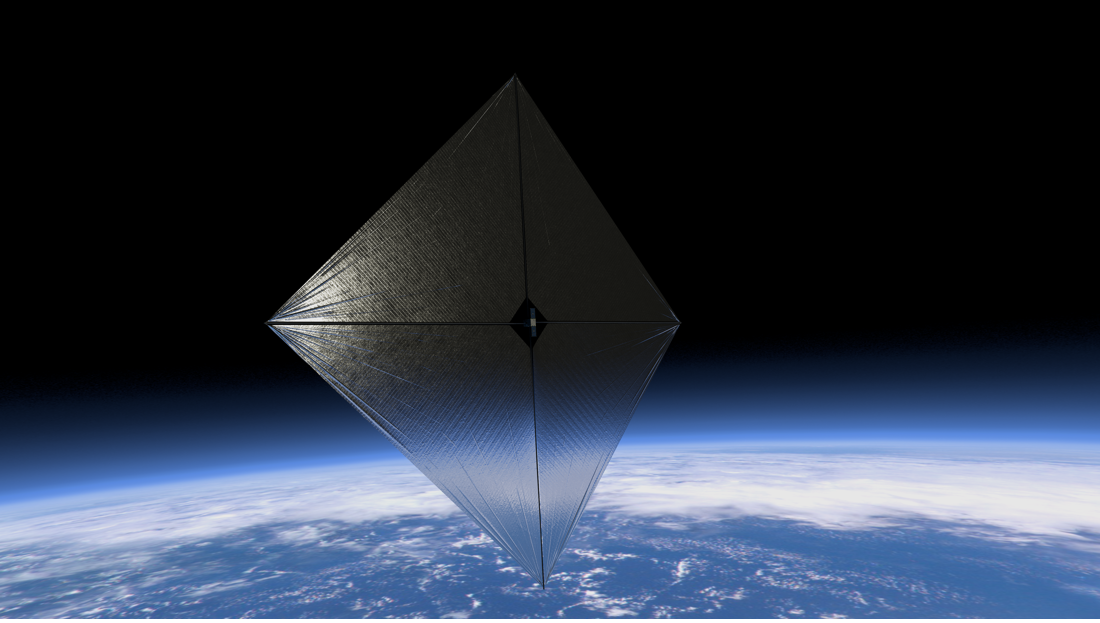

A rendering of the ACS3 solar sail in orbit. (Image source: NASA)

This is where the new composite craze comes into play.

Johnny Fernandez of NASA’s Langley Research Center told the National Science Foundation that while retractable boom technology has been around for quite some time, until now, it was made of carbon fiber reinforced polymer materials. Small satellite deployment solutions are possible.

Now, by making materials ultra-thin, we can use laminates [and] Fernandez says multilayer composites were not possible 10 or 15 years ago.

Composite boom material being tested on ACS3. (Image source: NASA)

While collapsible booms have been used on the Viking Mars landers as early as the 1970s, they were primarily made of metal. Problems can occur when they are exposed to sunlight for extended periods of time.

Fernandez points out that the use of metal versions has its limitations in terms of thermal expansion. It will deform like a taco-shaped structure.

The same concerns arose when designing the NEA Scout mission, which flew aboard Artemis 1 but never made contact with ground controllers after launch.

Fernandez said Langley studied structural stability, and when we looked at the thermal performance, it became apparent that the boom would slowly deform, rendering it unable to fly, so it quickly turned into a different study to find relief openings. .

Another question arises when looking at how prosperity extends. Fernandez noted that a mission like NEA Scout would split the membrane into four parts, exposing metal booms that could deform.

The team is studying the ACS3 solar sail, which is opened using a new composite boom. (Image source: NASA)

This problem led to a switch to a single membrane. The question then becomes where to place the fence and what materials to use.

Fernandez said we had to change from a quarter configuration to a single square in order to put the boom and sail at the back and the sail would act as a shade. This sparked interest in finding these thermally stable versions.

After reaching the planned orbit, ACS3 will deploy solar cells and then sail within 25 minutes using four new composite booms. The speed of deployment will be monitored by multiple cameras to understand efficiency and how well the sail’s shape is maintained.

Animation of ACS3 deployment sequence. (Image source: NASA)

When deployed, the square sail is approximately 9 meters (30 feet) long on each side.

The shape will continue to be monitored as testing begins using the sail itself.

Fernandez said if the film could be deployed and stretched during an event and camera data obtained, it would have been successful. The second goal is to use it.

Another issue they had to overcome was the deployment mechanism inside such a small CubeSat.

So this is only 40% of the prototypes NASA plans to use in the future.

Fernandez noted that this was a test of a larger-scale system, so we wanted to test the same types of materials a larger boom structure should use to accommodate a CubeSat by using the same materials. We are really approaching the limits of this technology.

The team works on the CubeSats that will be deployed by ACS3. (Image source: NASA)

He mentioned that a six times larger version of ACS3 is currently under development, and the sail team is working with the team at the German Aerospace Agency DLR to study the physical deployment mechanism.

Fernandez said the technology is now being used commercially, including by licensing a boom in deployable communications antennas. However, he said NASA is interested in the data, especially in connection with the Artemis moon landing program.

[NASA] The same type of roller structure is being used to deploy towers on the lunar surface, including solar panels or deployable antennas to communicate with the moon [the] Fernandez said Lunar Gateway.

The lunar dish dishes and reflectors currently being studied use grids, which Fernandez said creates its own problems.

Mesh reflectors are prone to dust problems on the moon, Fernandez said, so we wanted a solid surface, like a saucer on Earth… rather than creating a parabolic dish that folds like an umbrella.

Having tested the materials in parabolic microgravity flights, the team is working with industry and academia to ensure the mission is successful.

A rendering of the ACS3 solar sail fully deployed in orbit. (Image source: NASA)

Also participating in this mission is the New Space Earth Observation Satellite 1 (NeonSat-1). The high-resolution optical satellite was developed by the Satellite Technology Research Center (SaTReC) of the Korea Advanced Institute of Science and Technology (KAIST), South Korea’s leading science and technology institution, and will be deployed as a technology demonstrator for planned future Earth observation constellations.

If all goes well with this prototype flight, the Korea Advanced Institute of Science and Technology plans to mass-produce 10 more satellites, bringing the total number of satellites in the constellation to 11.

Both satellites are aboard Rocket Lab Electron rockets. On the company’s fifth mission in 2024, the first stage’s nine Rutherford engines, along with vacuum-optimized versions of the engines, will do most of the heavy lifting.

Electron payload fairing encapsulating the NEOSAT-1 and ACS3 payloads. (Image source: Rocket Lab)

The mission includes an additional third phase called the Kick Phase. It uses a Curie engine that can be fired multiple times to help lift and loop the orbit.

Rocket Lab notes that this mission is unique because it places two different spacecraft in very different orbits. Therefore, during this flight, the launch stage completed four different burns, including a final burn, to accelerate destructive reentry after satellite deployment.

NEONSAT-1 was deployed into a 520-kilometer (323-mile) circular Earth orbit tilted 97 degrees approximately 50 minutes after launch.

The second payload, ACS3, was deployed into a 1,000-kilometer (621-mile) circular Earth orbit that was also tilted 97 degrees. This deployment occurred approximately 1 hour and 45 minutes into the mission.

(Main image: Team work before NEONSAT-1 launch. Image source: Rocket Lab)

#Rocket #Lab #Flight #Unveils #Solar #Sailing #Technology #NASASpaceFlight.com

Image Source : www.nasaspaceflight.com