• physics 17,70

real time On the spot X-ray observations of new nickel-rich lithium-ion batteries indicate that performance degradation is caused by lithium ions becoming trapped in the cathode.

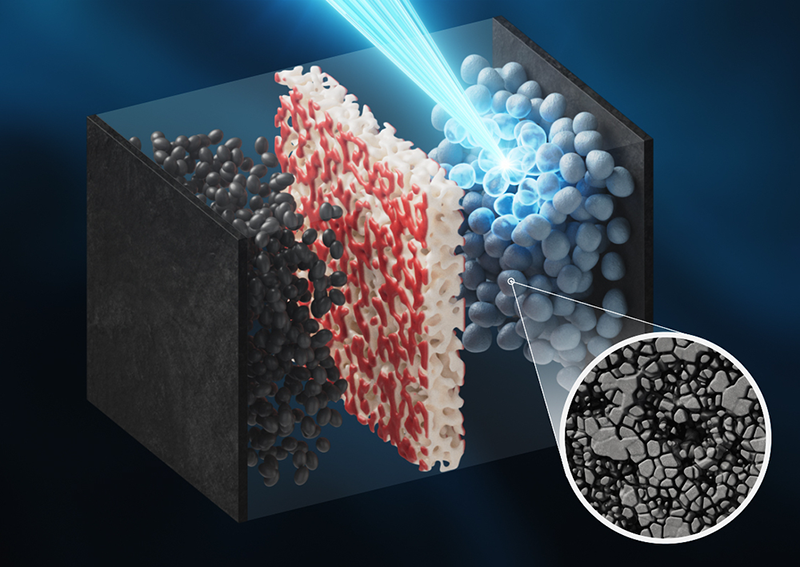

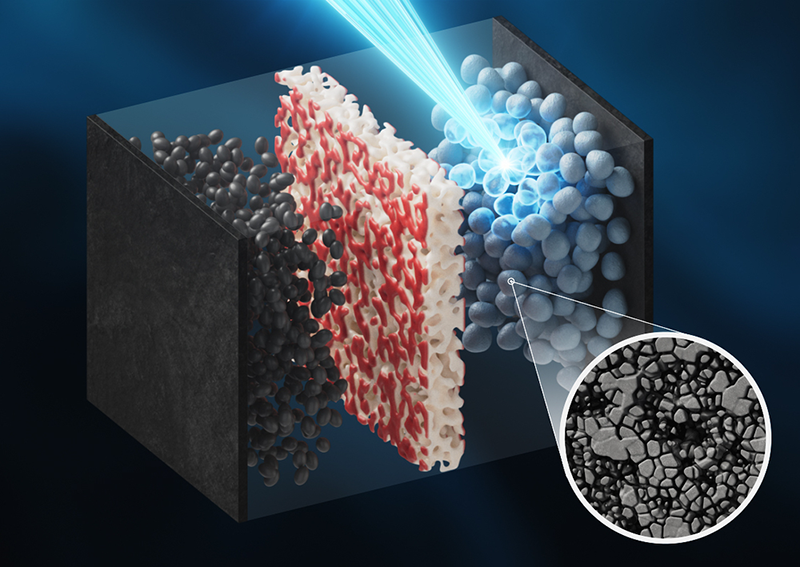

APS/Ella Maru Studio

This article is part of a series on advances in sustainable battery technology journal of physics This book is published to celebrate Earth Week 2024. Q: A vocational degree requires an electrochemist.

Electric vehicles are gaining more and more attention from the public.But their adoption has been slowed by the fact that batteries degrade over time, a problem that commercial companies are particularly keen to solve as they adopt more and more nickel-rich cathodes – cathodes Today’s newspaper Suitable for high-end electric vehicles. Replacing cobalt with nickel in early versions of these cathodes improved their performance but also accelerated degradation.Earlier this year, Louis Piper and colleagues at the University of Warwick in the United Kingdom designed and demonstrated an X-ray technique that can instantly inspect industrial-grade versions of nickel-rich lithium-ion batteries. [1]. Their observations help narrow down the reasons for these battery performance declines and provide recommendations on how to extend battery life.

The first commercially successful lithium-ion battery cathode consisted of alternating layers of lithium and cobalt oxide. This cathode delivers 140 milliamps (mAh/g) of current per gram of material, indicating that it uses only 50% of the lithium in the cathode. The discovery sparked a decades-long race to replace nickel with cobalt, as predictions suggested it would increase lithium utilization in the cathode to 70%, increasing the actual energy capacity of batteries. Such a shift could also avoid the need for cobalt, which is toxic and associated with unethical supply chains. But achieving the expected energy capacity of 200 mAh/g for lithium-nickel batteries has proven difficult due to increased cathode degradation. “The biggest issue is closing the gap between theory and practice [energy] Capacity of layered oxide cathodes,” Piper said.

Progress is being made. For example, Tesla’s new 4680 cylindrical battery uses a cathode that contains 80% nickel. These cells have high electrochemical performance, which is a direct result of the nickel-rich layer allowing more lithium ions to flow. Additionally, the design appears to benefit from the single-crystal nickel-rich cathode’s ability to relieve stresses that previously caused other cathodes to crack and degrade.

But these batteries still degrade. Post-use microscopy studies of such cells have shown that the cells degrade as oxygen leaches from the nickel-rich cathode. To figure out exactly why these batteries degrade, the researchers wanted to observe what happens inside the batteries as they go through charge and discharge cycles. This feat has proven difficult to accomplish because researchers often cannot understand reactions in full-scale cells because cells are multilayer sandwiches with many buried interfaces, making it difficult to probe the system using standard laboratory setups.

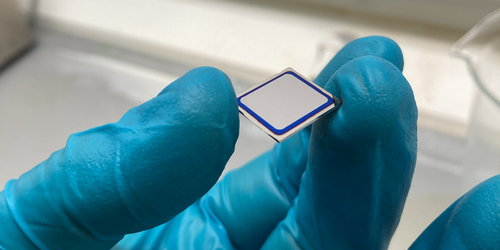

In the experiment, Piper and his team studied industrial-grade nickel-rich lithium-ion batteries they made on a pre-commercial production line. Perform accelerated charge-discharge cycles on the battery. The researchers integrated the batteries into an X-ray diffractometer and exposed them to the high voltages, charging speeds and depth of charge (the “fullness” of a battery’s charge) experienced by commercial batteries.

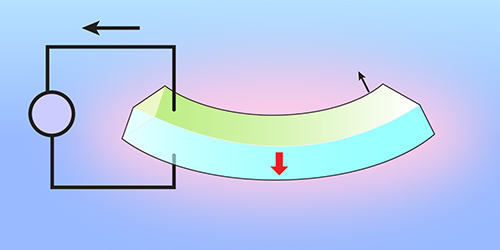

Live X-ray data collected during charge and discharge cycles revealed that the surface structure of the nickel-rich cathode undergoes chemical changes at high voltages. The team found that the nickel-rich surface lost oxygen and was mostly oxidized. This change leads to the formation of an oxygen-poor surface layer that traps lithium ions, resulting in a 10% capacity drop after 100 cycles. “You end up with a reduced rock salt nickel oxide shell, about 2 to 5 nm thick, which acts as a kinetic trap and slows down the extraction and insertion of lithium,” Piper said. Further experiments showed that slowing down charging and discharging could ease lithium’s “traffic jam” but not completely reverse it.

“We can draw a lot of conclusions about how batteries degrade based on the electrochemical data,” says Yulia Preger, a chemical engineer at Sandia National Laboratories in New Mexico. But “material characterization methods like this can provide new insights that help us design Better materials to make better batteries,” agrees Jacqueline Edge, a battery scientist and physicist at Imperial College London. Piper proposed that doping or coating the cathode surface with aluminum or aluminum oxide could help passivate the nickel surface and prevent lithium traffic. “New laboratory [measurement] The methodology provides a faster way to validate physics-led designs for industrialization,” she said.

Rachel Berkowitz

Rachel Berkowitz is the author ofjournal of physics Headquartered in Vancouver, Canada.

refer to

- as menon et al.Quantifying electrochemical degradation of single crystal LiNi0.8manganese0.1cobalt0.1oxygen2Graphite soft pack battery passed operate X-ray and autopsy investigations, PRX Energy 3013004 (2024).

academic area

#Lithiumion #traffic #congestion #reduces #battery #performance

Image Source : physics.aps.org