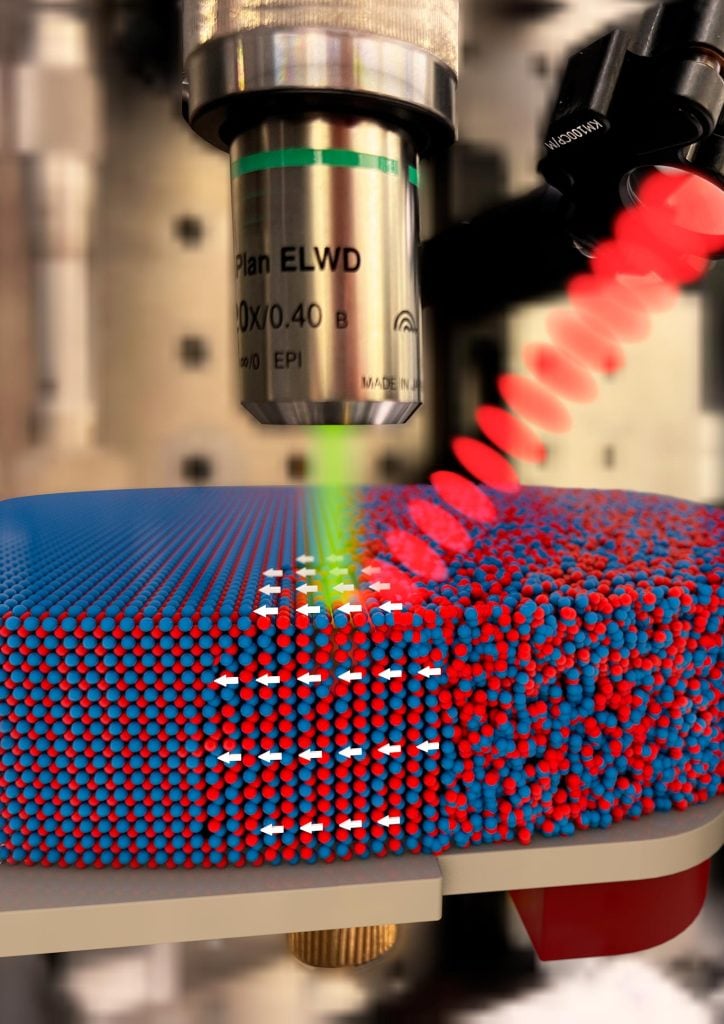

If a strong laser pulse hits an iron alloy, the material briefly melts and forms tiny magnetic areas at the point of exposure. Photo credit: HZDR / Sander Münster

A research team has discovered that ultrashort laser pulses can magnetize iron alloys, a discovery that has huge potential for applications in magnetic sensor technology, data storage and spintronics.

To magnetize an iron nail, simply tap a magnet on its surface a few times.However, there is a more unusual method: by Dresden-Rosendorf Helmholtz Center (HZDR) A certain kind of iron was discovered some time ago alloy Can be magnetized with ultra-short laser pulses. The researchers have now teamed up with the Laserinstitut Hochschule Mittweida (LHM) to further study this process. They found that this phenomenon also occurs with different classes of materials, which significantly broadens the potential applications.The working group published its findings in the scientific journal Advanced functional materials.

Breakthrough discovery in magnetization

This unexpected discovery was made in 2018. When the HZDR team illuminated thin layers of iron-aluminum alloy with ultrashort laser pulses, the non-magnetic material suddenly became magnetic. Explanation: The laser pulses rearrange the atoms in the crystal, bringing the iron atoms closer together, creating a magnet. The researchers were then able to demagnetize the layer again with a series of weaker laser pulses. This allowed them to discover a way to create and erase tiny “magnetic spots” on surfaces.

However, the pilot experiment still leaves some unanswered questions. “It is not yet clear whether this effect occurs only in iron-aluminum alloys or also in other materials,” explains HZDR physicist Dr. Rantej Bali. “We also wanted to try to track the temporal progression of the process.” To To further his research, he collaborated with Dr. Theo Pflug of the LHM and colleagues at the University of Zaragoza in Spain.

Laser pulse flip book

Experts are paying particular attention to iron-vanadium alloys. Unlike iron-aluminum alloys with regular crystal lattice, the atoms in iron-vanadium alloys are arranged more chaotically, forming an amorphous glass-like structure. To observe what happens when laser irradiation occurs, physicists use a special method: the pump-probe method.

“First, we irradiate the alloy with intense laser pulses to magnetize the material,” explains Theo Pflug. “At the same time, we use a second, weaker pulse that reflects off the surface of the material.”

Analysis of reflected laser pulses provides an indication of the material’s physical properties. This process is repeated several times, so that the time interval between the first “pump” pulse and the subsequent “detection” pulse is continuously extended.

As a result, a time series of reflection data is obtained, which enables the characterization of processes triggered by laser excitation. “The whole process is similar to generating a flip book,” Pflug said. “Similarly, a series of individual images animates when viewed in rapid succession.”

melts quickly

Results: Although the atomic structure of iron-vanadium alloys is different from that of iron-aluminum compounds, iron-vanadium alloys can also be laser magnetized. “In both cases, the material melts briefly at the point of irradiation,” explains Rantej Bali. “This causes the laser to erase the previous structure, creating a small magnetic region in both alloys.”

Encouraging results: Apparently, this phenomenon is not restricted to a specific material structure, but can be observed in different atomic arrangements.

The team is also tracking the temporal dynamics of this process: “At least we now know on which time scale something happens,” explains Theo Pflug. “Within femtoseconds, the laser pulse excites electrons in the material. After a few picoseconds, the excited electrons transfer energy to the nucleus.”

This energy transfer therefore leads to rearrangement into a magnetic structure, which is stabilized by subsequent rapid cooling. In follow-up experiments, the researchers aim to observe exactly how the atoms rearrange themselves by examining the magnetization process using powerful X-rays.

Focus on applications

Although still in its early stages, this work already provides early ideas for possible applications: for example, it is conceivable to place tiny magnets on the surface of a wafer via laser. “This could be useful for producing sensitive magnetic sensors, such as those used in vehicles,” Rantej Bali speculates. “It could also find possible applications in magnetic data storage.”

Furthermore, this phenomenon appears to be related to a new type of electronics called spintronics. Here, magnetic signals should be used in digital computing processes, rather than passing electrons through transistors as usual – providing a possible approach for future computer technology.

Reference: “Laser-induced positional and chemical lattice rearrangements generate ferromagnetism” by Theo Pflug, Javier Pablo-Navarro, Md. Shabad Anwar, Markus Olbrich, César Magén, Manuel Ricardo Ibarra, Kay Potzger, Jürgen Faßbender, Jürgen Lindner, Alexander Horn and Lantei Bali, November 21, 2023 Advanced functional materials.

DOI: 10.1002/adfm.202311951

#Laser #pulse #magnetization #future #twist #materials #science

Image Source : scitechdaily.com