Before sending any device into space, NASA attempts to limit and plan for any failures through exhaustive testing of the individual cells within the battery.

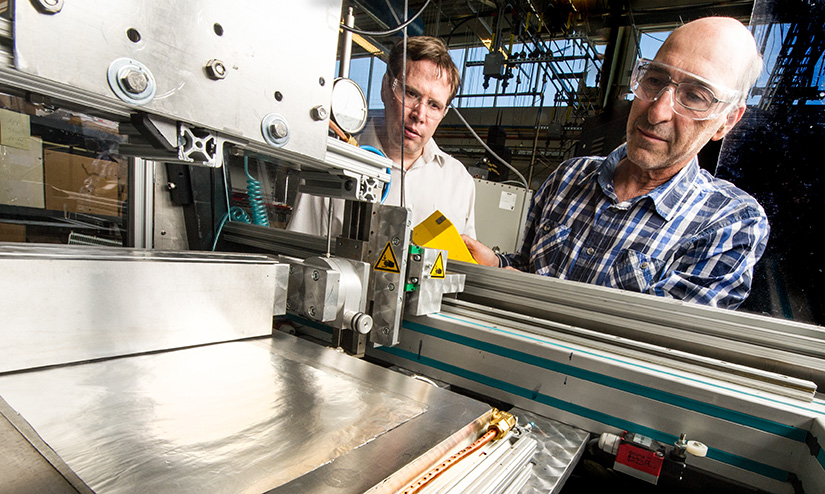

To do this, NASA and the National Renewable Energy Laboratory (NREL) created a device that causes an internal short circuit inside the battery layer, by melting a thin layer of The wax is used to intentionally damage the cell and force the test cell to a precise time and location within the cell. This information enables NASA to meet its stringent battery safety requirements.

Matt Keyser, senior energy storage engineer at NREL, said that if you know how a battery will respond to an internal short circuit, you can come up with ways to make the battery safer. Once you understand how it failed, then you can look at the methods available to address the point of failure.

This is critical for testing batteries on the International Space Station, Artemis missions to the moon, and future missions to Mars.

Internal short circuit device (ISC-D) triggering unit is our preferred method of disposing of batteries Eric Darcy said that the testing activities of all our manned missions, Battery Technology Discipline Lead at NASA’s Johnson Space Center.

Keyser, a 31-year NREL veteran, was part of the team that originally created ISC-D, along with NREL chief energy storage engineer Ahmad Pesaran and NASA engineer Eric Darcy.

Darcy said, As early as 2010, I received a sabbatical from NASA to work at NREL for one year. I was in Golden, Colorado, and I invented the internal short circuit device with Matt Keyser. It barely worked, but we did a proof of concept that year. By 2014, we were finally ready for prime time.

Goldilocks Wax Turns Out to Be Great for ISC-D

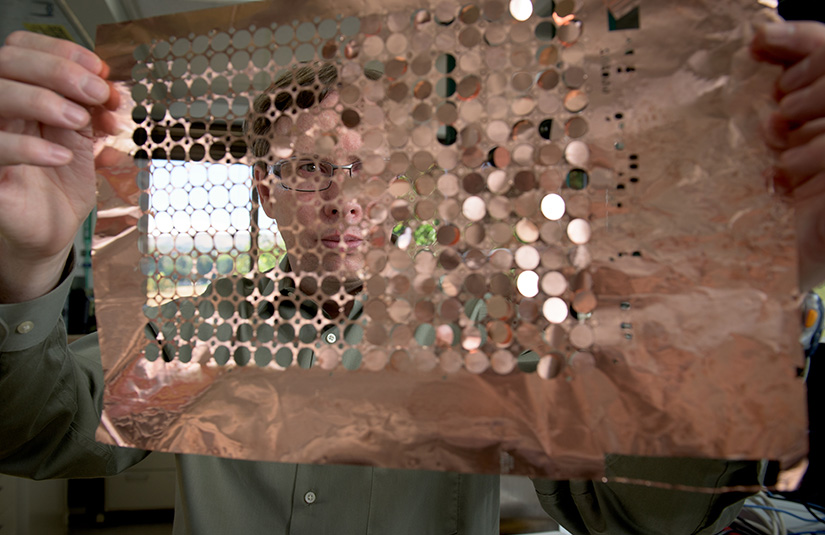

The device is implanted into the battery by the manufacturer between the anode and cathode, becoming a specially triggered battery with on-demand internal shorting points. Once the insulating wax melts, the battery can experience a hard short, like an internal short caused by a single-point manufacturing defect.

These defects still plague the lithium-ion battery industry and lead to rare but catastrophic field failures in batteries. The ISC-D method is more representative of these field failures than the standard pinning method and can cause multiple internal shorts or thermal triggers in the cell, melting a large portion of the separator between the anode and cathode above 130°C. Spend degrees Celsius.

“We went through all the iterations of the device and it wasn’t quite right,” Kaiser said. When Eric began his vacation, he suggested trying paraffin wax as an insulator.

Paraffin wax turned out to be too brittle, so Keizer worked on microcrystalline wax, which was too soft. Goldilocks wax is a blend of paraffin wax and microcrystalline stone. The wax also has a melting point of 57 degrees Celsius, which is much lower than other forms of testing.

Darcy said that due to testing campaigns using ISC-D trigger cells, battery designs for nearly all human spacecraft applications have been proven to resist the propagation of thermal runaway from cell to cell. This approach ensures that the risk of over- or under-testing is minimized when a single-cell thermal runaway (TR) event is triggered in a battery with multiple cells. A properly designed cell can withstand a single-cell TR event at any location without propagation, which would only reduce performance. Conversely, if TR spreads from one cell to another, it could mean catastrophic failure. It can shoot down the capsule, causing loss of vehicles and/or personnel.

Technology licensing enables full commercialization

After the team got ISC-D working so that large test cells could be assembled from these trigger cells, the technology won an R&D 100 award and NREL began working with a company called KULR Technology Group to license the technology from NREL matters to be negotiated. NREL licenses its technology to companies through its Technology Transfer Office because the lab prioritizes research over mass production.

Kaiser said researchers aren’t ready to make hundreds of devices over and over again in exactly the same way. We research new inventions and, if they work, move them to industry and progress to the next project.

NREL granted an exclusive license to KULR in 2018, and the company now sells ISC-D to a variety of battery manufacturers, including those that supply NASA, meaning the technology has come full circle.

Will Walker, chief technical officer of KULR and a former NASA battery engineer, said, “At KULR, we focus on all things related to battery safety.

What does it mean to design a safe battery and demonstrate safety in the form of tests?

Walker said there are significant difficulties with battery pack and system-level thermal runaway testing. The advantage of ISC-D cells is that they can be triggered at a lower controlled temperature, thereby reducing bias from adjacent cells in the experiment. The result is an overall less invasive triggering method.

Under the licensing agreement, KULR has exclusive rights to sell ISC-D and cells implanted with ISC-D.

Walker says it’s a very elegant solution. For KULR, we want to be at the forefront of cutting-edge technology related to safety, which is the only truly non-invasive triggering method available.

The batteries NASA is testing at ISC-D include batteries in new astronaut suits, equipment and crewed spacecraft.

Recently, a university group came to NREL to demonstrate the best way to test internal batteries. Keyser was in the audience when the panel concluded that the NREL team’s ISC-D technology was the best.

“That’s very satisfying to me,” Keizer said. The technology we developed is the best for simulating internal short circuits.

The ISC-D can also be used to test electric vehicle or grid batteries. Keyser also hopes some testing organizations will adopt the technology as part of their processes.

There are a lot of manufacturers using this technology, but I would like to see it incorporated into testing procedures and protocols to make batteries safer,” Keyser said. Our technology is the only one capable of simulating a true internal short circuit, providing battery engineers with an accurate picture so they can design safer battery systems.

Learn more about NREL Energy storage research and Sustainable transport and mobility research. and subscribe to NREL’s quarterly transportation and travel research newsletter, Sustainable transportation is importantfor the latest news.

#Deliberate #short #circuit #NRELlicensed #technology #continues #space

Image Source : www.nrel.gov